Request the password for the reserved area by sending us your email:

Thank you for contacting us.

We will get back to you as soon as possible.

An error occurred while sending the message.

Please try again at a later time.

Service

The service

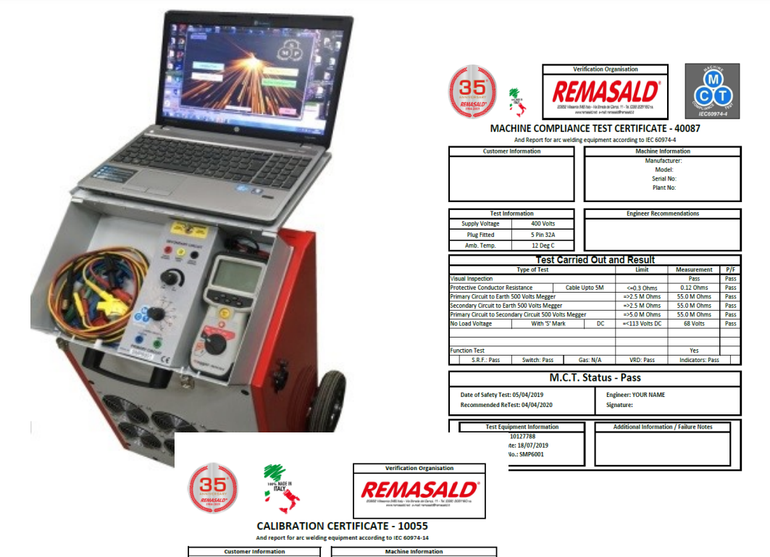

The entry into force of the Standard IEC 60974-14 specifies new requirements for the verification of arc welding and external monitoring equipment, including the verification of welding machines. This monitoring is carried out by measuring certain essential characteristics, including the verification of electrical parameters, measured gas flow and wire feed rate. The guidelines dictated by the standards regulating quality management systems in welding indicate the annual frequency of these checks.

REMASALD uses a technological device capable of managing and controlling welding parameters, and correct operation of the welders directly in the field, without making any modifications to the welders.

Who it is aimed at

Companies certified EN 1090, 3834,15085, 9001, NADCAP are obliged to have a methodical welding machine testing system.

The entry into force of this standard means that welding machine calibrations are no longer carried out using current clamps with sensitivities well in excess of 2.5 per cent, but through the use of instrumentation that allows the parameters required by the standard to be measured as a primary instrument.

Welding machine inspection service

The entry into force of the IEC 60974-14 standard specifies new requirements for the verification of arc welding and external monitoring equipment, including the verification of welding machines. This monitoring is carried out by measuring certain essential characteristics, including the verification of electrical parameters, measured gas flow and wire feed rate. The guidelines dictated by the standards regulating quality management systems in welding indicate the annual frequency of these checks.

REMASALD uses a technological device capable of managing and controlling the welding parameters, and the correct operation of the welders directly in the field, without making any modifications to the welders.

In addition, REMASALD issues a “electrical safety report according to CEI EN 60974-4”, required by law, relating to any brand and type of arc welder.

Service opportunities

Effective monitoring of the welding process enables ensure that the correspondence between the essential parameters entered into the welder (generator, torch, accessories) are in line with the tolerance limits in the WPS.

This control ensures repeatability in the execution of a welded joint, guaranteeing high quality levels in terms of mechanical and chemical characteristics.

HEAD OFFICE

CONTACT DETAILS

Fax: +39 039 2051 162

sales@remasald.it